|

|

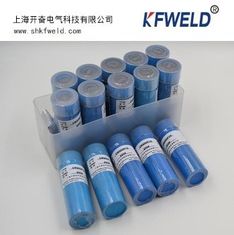

Exothermic Welding Metal Powder, Thermit Powder, with ignition powder, good quality, nice price

Product Details:

Payment & Shipping Terms:

|

| Product Material: | Cu,Al,Cu2O | Specification: | 65g,90g,115g,150g,200g,250g, 300g, 350g. |

|---|---|---|---|

| Usage: | Exothermic Welding | Including: | One Copper Disc, Ignition Powder And Exothermic Welding Flux |

| Package: | Bag Or Plastic Bottle + Carton+wooden Case |

KFWELD exothermic welding powder can be used to restore metal compounds and a certain percentage of the reduction of substances, and made by a special process. All products through the China National Nonferrous Metals Research Institute test center monitoring, product quality comparable to the well-known manufacturers of products, supporting KFWELD mold and accessories, to meet all the copper, copper clad steel materials, steel grounding welding requirements. Each bag welding powder standard with a bag ignition powder and disc steel plate.

1.KFWELD welding powder is a non-dangerous goods, the use of sealed waterproof design, solder powder does not contain phosphorus, magnesium and other harmful materials on the human body to facilitate transport and storage.

2. Product performance and stability, low porosity, in strict accordance with the construction process, can ensure that the solder porosity <1%.

3. Welding different types, specifications of metal quality, such as welding, according to different materials to provide different formulations of the solder powder, and according to different ways to provide accurate component packaging, through the reaction temperature and speed control, adjust the solder element composition and Ratio, so as to achieve the best welding performance, in the full guarantee of the quality of welding under the premise of the degree of standardization, not only to minimize the damage to the metal base metal damage, but also greatly improve the service life of the mold.

4. Welding powder reaction is full, very little solder impurities, solder joint conductivity and corrosion resistance is extremely high.

Exothermic welding powder specification:

| Part No. | Specification | Part No. | Specification |

| KFWELD65 | 65#,65gram | KFWELD200 | 200#,200gram |

| KFWELD90 | 90#,90gram | KFWELD250 | 250#,250gram |

| KFWELD115 | 115#,115gram | KFWELD300 | 300#,300gram |

| KFWELD150 | 150#,150gram | KFWELD350 | 350#,350gram |

![]()

Exothermic welding operation process:

1. Clean the joint of the mold and the welded conductor and place the welded conductor at the central position of the mold cavity;

2. Close the mold and arrange a metal protective ring at the bottom of the mold smelting furnace;

3. Pour in the hot fusion welding and spray pyrophoric powder on the surface, to the mold mouth, of the flux;

4. Cover the mould cover and ignite the pyrophoric powder at the mould mouth by using a burning torch;

5. The hot fusion melting flux is subjected to high temperature reaction in the mould after being ignited;

6. Open the mould after natural cooling when the reaction is finished.

Matters Needing Attention:

1. Unrelated person should not stay within 1.5 meters away from the operation site during construction.

2. Inflammable goods should not be placed within 1.5 meters away from the operation site during construction.

3. The operating personnel must put on heat-resisting working gloves.

4.The operating staff should not perform construction in front of the mouth of melted mold.

5. The operating staff should be at least 1.5 meters away from the melted mould immediately once the pyrophoric powder is ignited.

6. No one could contact the melted module directly after fusion welding is finished.

7. The melted module and the welded wire are cooled for 30 seconds after fusion welding is finished and then taken out by using a pincer.

8. Welded wire is subjected to insulation treatment only when the wire is completely cooled.

![]()

Exothermic welding type:

Bar to bar, bar to ground rod, bar to steel surface, cable tp bar, cable to cable, cable to ground rod, cable to re-bar, cable to steel surface, cable to rail, bolt to steel surface, one-joint.

![]()

![]()

Exothermic welding feature:

1. Current carrying capability from welding point is same as conductor with good conducting performance. After inspection, the DC resistance ratio and change rate are almost zero before and after welding. This is the level that any of the traditional welding method cannot be compared.

2. No need of resources from outside. It can be operated indoor and outdoor.

3. It won't be damaged by surge current. The test shows the conductor will be melted earlier than welding points when under high current impact in short period.

4. Corrosion or slack will not be produced from welding. As it is weld junction,no contact surface, no residual stress, junction is stable and reliable as long term conductive body.

5. As it is welding junction, connector and conductor are combined on molecular.So it has a good mechanical strength and is a permanent junction.

6. Equipment is simple, convenient and handy. The operation is easy and can be done.

Contact:

KFWELD Electrical Technology Co., LTD

Miss Summer

TEL: 86-21-34977237

FAX: 86-21-34110771

MOB: 86-13917179469

Email: summer@shkfweld.com sales@shkfweld.com admin@shkfweld.com

QQ: 1441294061

Skype: lkqf1985

WeChat: lkqf214

Website: www.shkfweld.com

-

Exothermic welding metal powder for earthing material connection, 200g, 150g, discount price, customized

-

Exothermic Welding Metal Powder, Thermit Powder, with ignition powder and steel plate

-

Exothermic Welding Mold Handle Clamp, Standard Model, High Qualtiy and Best Price

-

Exothermic Welding Powder, Exothermic Welding Metal, Thermit Powder

-

Exothermic Welding Mould, Graphite Mold,Thermal Welding Mold, with Mold Clamp

-

Exothermic Welding Flux, 115g/bag package, Exothermic Welding Metal Flux